HiMat-Chemical Engineering

Research Introduction

What is the Fundamental Properties Field?

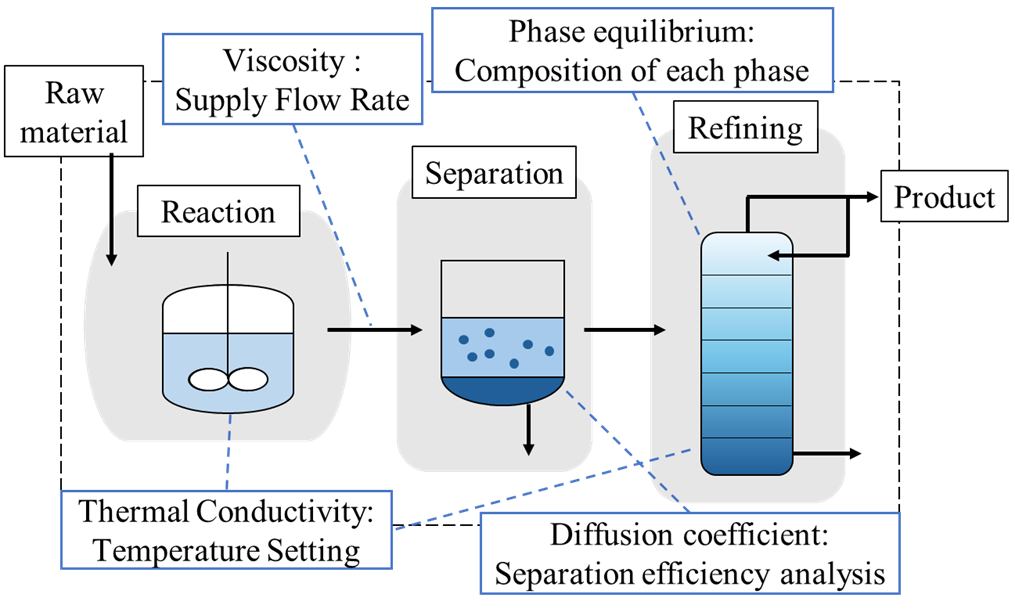

Chemical processes, such as reactions, separations, and purifications, all involve chemical engineering properties like phase equilibrium and viscosity. In other words, these properties are indispensable for designing such processes. While daily research and development yields numerous new chemical substances, there is, of course, no reporting of the chemical engineering properties necessary for using them in chemical processes. Measuring chemical engineering properties requires specialized equipment, expertise, and time. While these properties might seem like common knowledge, the reality is that only a handful of them are currently reported. Within chemical engineering, the field of fundamental properties research focuses on studying these very chemical engineering properties.

Within this field, the primary research focus is the measurement of chemical engineering properties. While measuring previously unmeasured targets is certainly a key task, developing new measurement methods is also a challenge.

Unfortunately, no matter how advanced measurement technology becomes, it is impossible to measure all the numerous targets. Therefore, alongside conducting measurements, it is necessary to predict chemical engineering properties. Prediction involves using existing models to establish correlations and make estimations, while also striving to improve accuracy and expand the scope. Developing new estimation models is also a challenge. However, prediction alone cannot verify whether precise properties are being predicted, making property measurement essential.

The field of fundamental physical properties requires both “measurement” and “prediction” approaches in chemical engineering physics.

Hybrid Physical Property Prediction Model Combining “Equation of State” and “AI”

We are developing a physical property prediction model that integrates equation of state and AI. We introduce specific research content and provide access to the actual prediction model we have developed.

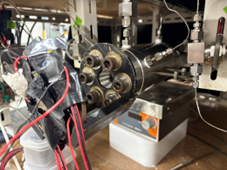

Chemical engineering property measurements difficult to perform with commercially available equipment

We not only predict properties but also fabricate and measure a wide range of chemical engineering properties from the equipment design stage. Here we introduce the chemical engineering properties we have measured to date.

“Electric Field Simulation” and “AI”

Hybrid Electrostatic Inkjet Printing Characteristic Prediction Model

We are also deploying AI-integrated prediction models in actual chemical processes. Here we introduce their application to the electrostatic inkjet printing process.

Hybrid Physical Property Prediction Model Combining “Equation of State” and “AI”

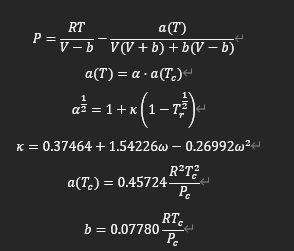

An equation of state (EoS) is used to correlate and predict various physical properties across a wide range of temperature and pressure conditions, from pure substances to mixtures. This is because it can determine not only the pressure-volume-temperature relationship but also various thermodynamic state variables. The equation of state typically taught in high school chemistry is PV=nRT. However, this is the ideal gas equation of state and cannot be applied to real substances. Therefore, numerous types of equations have been proposed to accommodate real substances. These equations of state are incorporated and used within process simulators, such as Aspen+ and PROII, which are essential tools for process design.

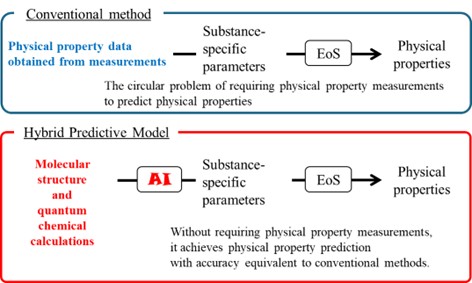

Calculations using a equation of state applicable to actual substances involve obtaining substance-specific parameters from measured physical properties, applying them to the equation of state, and predicting physical properties. This creates a circular problem where predicting physical properties requires known physical properties. To address this issue, we are developing a novel model that combines AI with an integrated “equation of state and AI” model to predict physical properties without requiring prior knowledge of those properties.

Research Findings

Peng-Robinson equation of state-van der Waals one fluid mixing rule, interaction parameters kij, lij between CO2 and organic solvents

Peng-Robinson equation of state

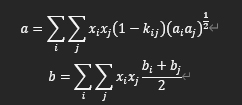

van der Waals one fluid mixing rule

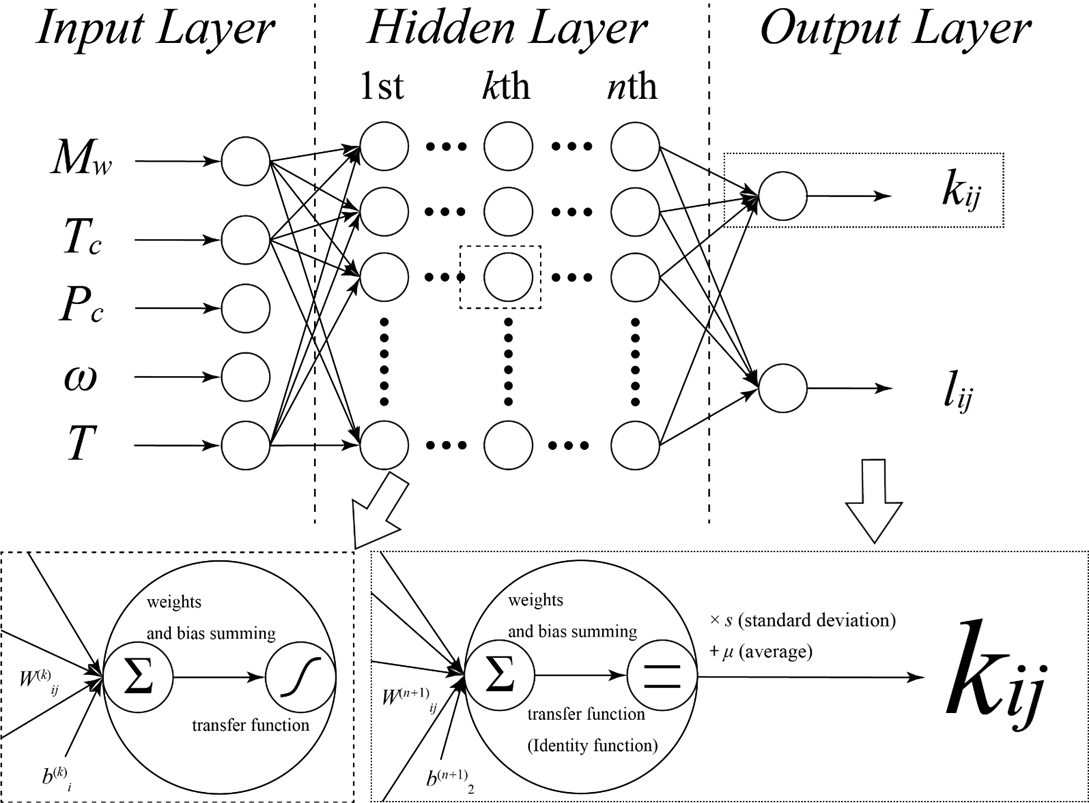

- Prediction model based on critical points and eccentricity factors of organic solvents

- Prediction model based on molecular information obtained from quantum science computing (future update)

- Prediction model based on molecular information of organic solvents in carbon dioxide using PCM theory (future update)

PC-SAFT Equation of State, Pure Component Parameters

- Prediction model based on group contribution method (molecular structure) (future update)

- Prediction model based on molecular information obtained from quantum science computing (future update)

- Prediction model treating molecular structure as graph structural information (future update)

Peng-Robinson Equation of State-van der Waals One Fluid Mixing rule, Interaction Parameters for CO2/Organic Solvents

- Hiroaki Matsukawa, and Katsuto Otake*, “Estimation of the interaction parameters between carbon dioxide and an organic solvent by the Peng–Robinson equation of state via an artificial neural network”, Fluid Phase Equilib., vol. 585, 114174 (2024). https://doi.org/10.1016/j.fluid.2024.114174

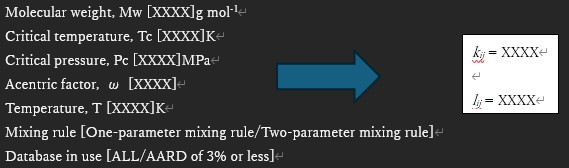

By entering the following information about organic solvents, the interaction parameters kij and lij can be predicted.

Chemical engineering property measurements difficult to perform with commercially available equipment

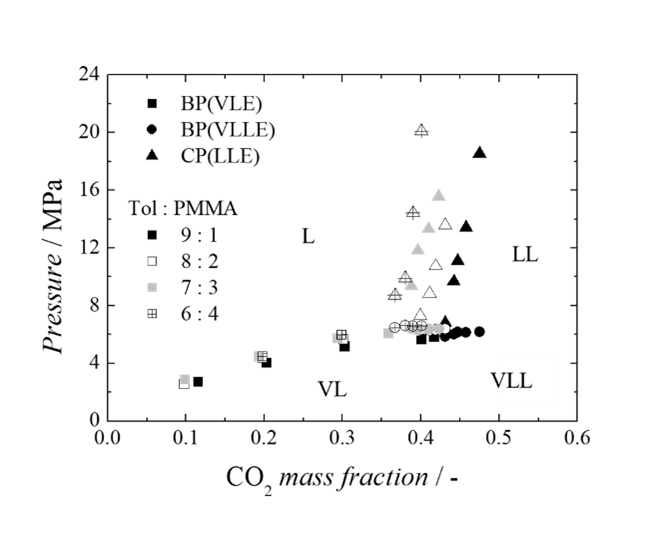

High-pressure phase equilibrium

Examples of Achievements

CO2/Dioctyl phthalate binary system

(https://doi.org/10.1016/j.supflu.2025.106589)

CO2/Tetrapropyl orthosilicate binary system

(https://doi.org/10.1016/j.fluid.2021.113172)

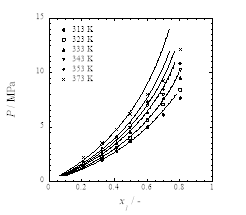

CO2/Toluene/Polystyrene ternary system

(https://doi.org/10.1016/j.fluid.2020.112464)

CO2/Toluene/Polymethyl methacrylate ternary system

(https://doi.org/10.1016/j.fluid.2024.114153)

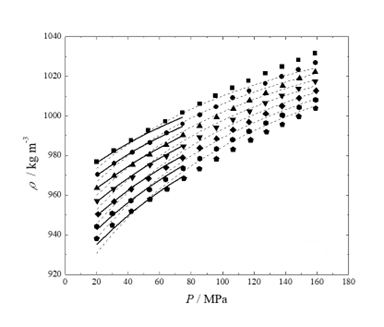

Pressure-Volume-Temperature relationships

Examples of Achievements

Tetramethyl orthosilicate

(https://doi.org/10.1021/acs.jced.9b00765)

Tetrapropyl orthosilicate

(https://doi.org/10.1021/acs.jced.1c00499)

Diisononyl phthalate

(https://doi.org/10.1016/j.supflu.2021.105330)

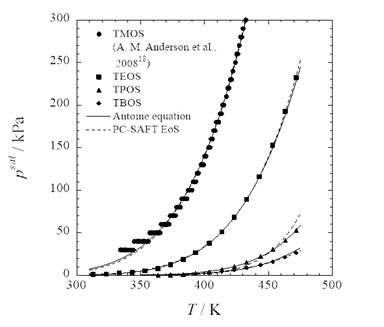

Saturated vapor pressure

Examples of Achievements

Tetraalkyl orthosilicates

(https://doi.org/10.1021/acs.jced.4c00325)

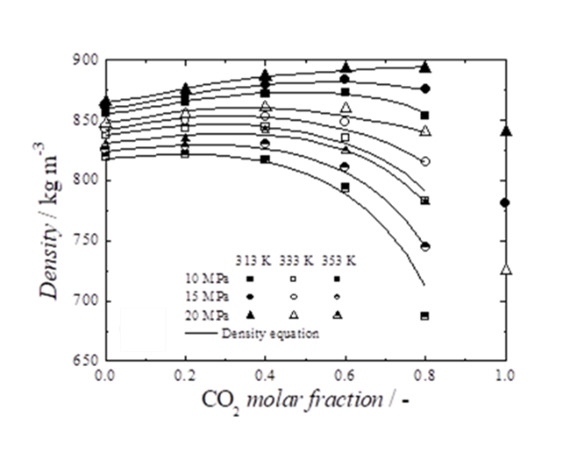

Homogeneous density of mixtures

Examples of Achievements

CO2/Cyclohexane binary system

(https://doi.org/10.1016/j.jct.2019.105902)

CO2/Toluene binary system

(https://doi.org/10.1016/j.jct.2021.106618)

CO2/Methanol binary system

(https://doi.org/10.1016/j.fluid.2024.114140)

and more…(Glass transition temperature, Interfacial tension)

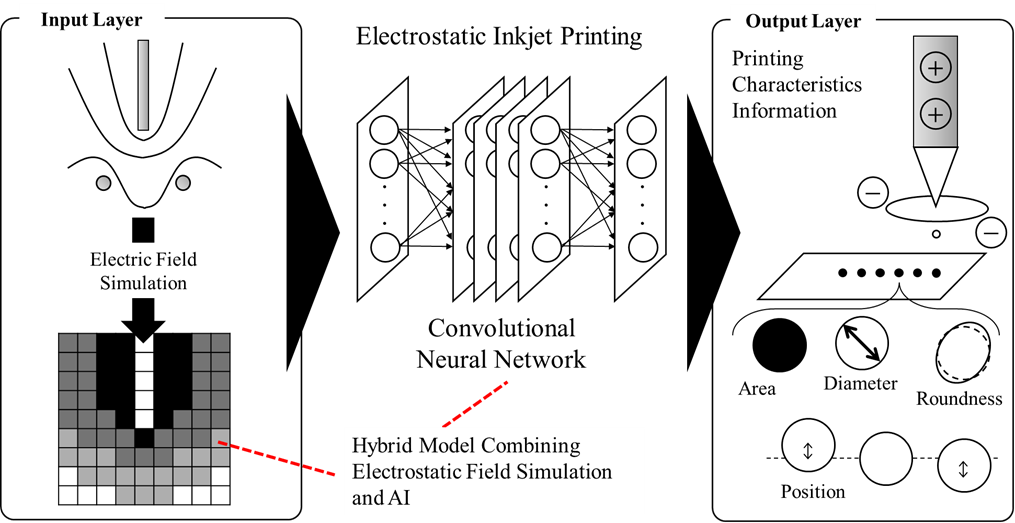

“Electric Field Simulation” and “AI” Hybrid Electrostatic Inkjet Printing Characteristic Prediction Model

Electrostatic inkjet is a microfabrication and microdeposition manufacturing technology that generates small droplets from the nozzle tip within an electrostatic field applied at high voltage and deposits them onto a substrate. However, the width of the printed droplets is significantly influenced by process and experimental parameters such as the electric field and material properties. Printing characteristics have been determined primarily through empirical methods. This research introduces convolutional neural networks, commonly used in image recognition, to achieve the parameterization of the difficult-to-represent electrostatic field shape. It forms a hybrid model combining electrostatic field simulation with AI. This establishes a universal printing characteristic prediction model for electrostatic inkjet, dramatically improving the design and optimization of the electrostatic inkjet process.